Ship to Shore Hose Range

Ship to Shore Hose Range - 102mm is backordered and will ship as soon as it is back in stock.

Make an enquiry

Make an enquiry

Want to make an enquiry on this product?

Please contact our sales team by telephone 01772 653530 or email sales@centuryhoseandcouplings.co.uk

About Ship to Shore Hose Range

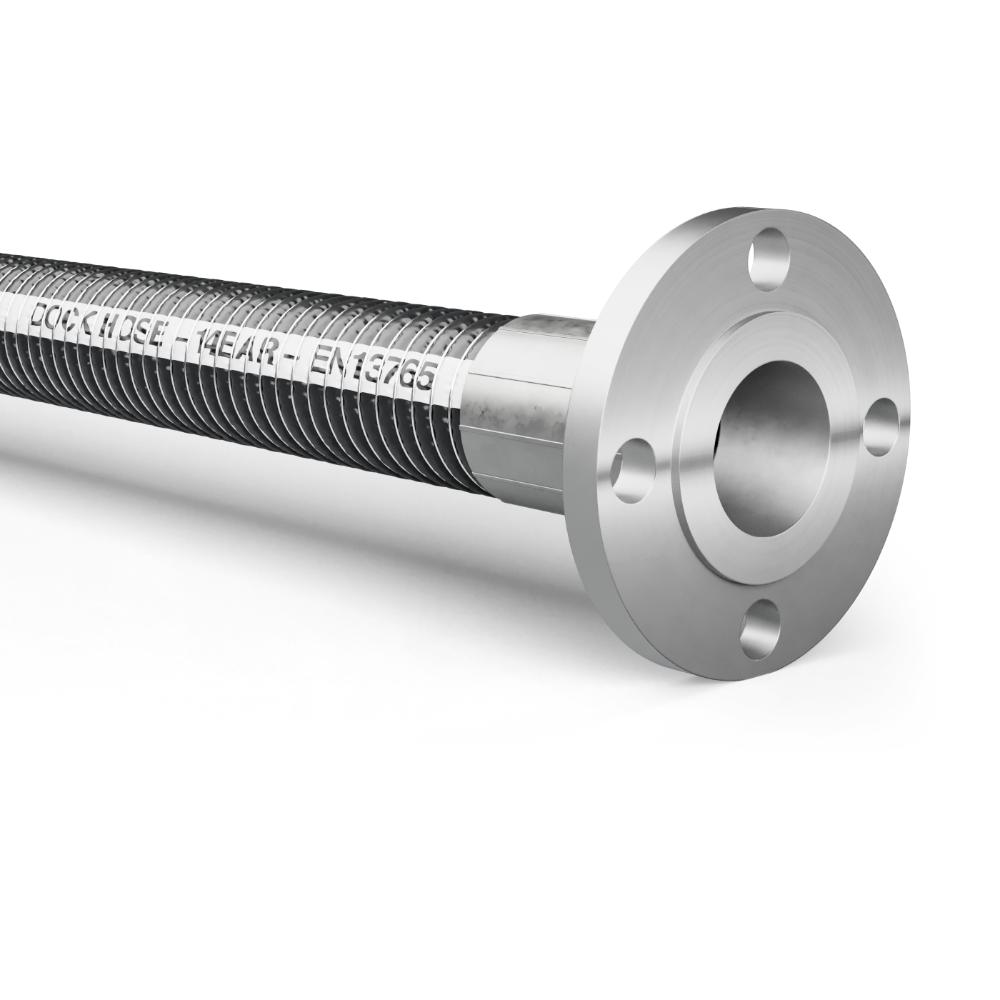

Construction

- Ship to Shore Hoses, with polypropylene construction, are resistant to a wide range of fuels and solvents.

- Pressure safety factor 5:1.

- For applications of a more corrosive, acidic and searching solvent nature, Ship to Shore hoses are available with a P.T.F.E lining and polypropylene-covered or stainless steel inner wires.

- Manufactured to meet bs 5842 1980 (BS EN 13765:2003) US Coastguard IMO standards.

- A wide range of factory-fitted end fittings are available for this product range. These fittings feature a helical swaging tail, ensuring electrical continuity is achieved across the length of the hose assembly.

- Maximum manufactured length: 25m for 4" NB, 20m for 6" and 8" NB and 15m for 10" NB.

Application

Designed specifically for the transfer of bulk chemical and petroleum products, and in particular, for dockside, and ship use.

Temperature range for polypropylene is -30°C to +80°C and for P.T.F.E is -30°C to +100°C.

About Composite Hose Assemblies

We supply bespoke manufactured Composite Hose Assemblies for hydrocarbon & chemical applications across a wide range of industrial sectors. We believe it is vitally important to use components that are FULLY COMPATIBLE and we do not 'mix and match' components from various manufacturers.

Having engineered companies within the R&G Fluid Power Group means we have the capabilities to design and fabricate fittings to manufacturers-approved dimensions to ensure safe, and compliant, assemblies.

All Composite Assemblies are constructed by qualified technicians who have passed our own Composite Assembly Training programme, ensuring you have peace-of-mind that the product has been made by a competent and accredited person.

We guarantee that every Composite Assembly we produce is 100% pressure tested and has full electrical continuity.

Assemblies are supplied with their own unique identification tag and a pressure test certificate.

We can manufacture to your specific requirements so please contact the CH&C team with your enquires!